Autotechnician article: How to choose the right charger

This month, we contributed to an article in Autotechnician's first digital magazine. Below is the full article:

Choosing the right charger

When choosing a charger, garages need to consider the range of battery types they will encounter. Traction Direct’s Managing Director Chris Walker says: “The ‘one-type-fits-all’ and ‘bigger-the-better’ approach to battery charging no longer applies. “Calcium/Calcium or Calcium/Silver types are used as starter batteries and on single battery vehicles.

However, vehicles fitted with two batteries can carry Absorbed Glass Matt (AGM) batteries to power their non-engine systems. “Both require different charging methods if they are to be correctly charged. Putting high current into a Calcium battery can damage it and be potentially dangerous, where an AGM type is more able to accept a higher charge.”

Sulphation is the name of the game

When a battery is low, the degradation can be caused by a number of factors. Let’s consider sulphation.

Over to Chris: “When a battery is left in a discharged condition, continually undercharged, or the electrolyte level is below the top of the plates, some of the soft lead sulphate re-crystallises into hard lead sulphate and cannot be reconverted. This creation of hard crystals is commonly called permanent ‘sulphation’. It accounts for approximately 85 per cent of the lead-acid battery failures that are not used weekly.

“Batteries naturally self-discharge one per cent to 60 per cent per month while not in use and sulphation will begin occurring when the State-of-Charge (SoC) drops below 100 per cent. Cold will slow the process down and heat will speed it up."

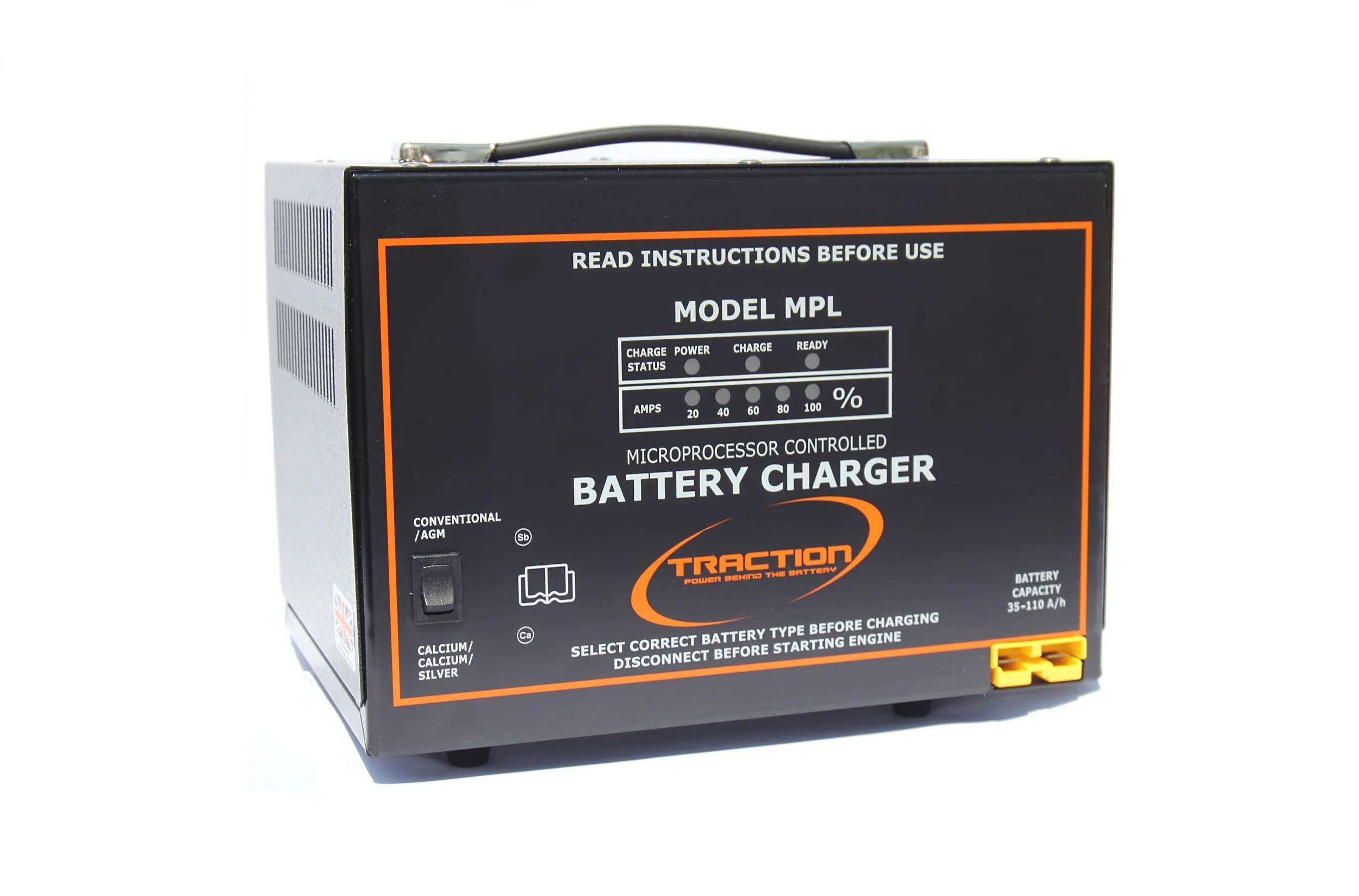

Traction knows a lot about sulphation: During the early 1980s, the company developed the MPL range of chargers for Delphi to charge the then new Calcium/Calcium battery. Traction also began work on a sulphation recovery process that could be incorporated into the design. The process was so innovative that it was patented by Traction Direct and has been at the core of the MPL range ever since.

“Most chargers need to ‘see’ more than eight volts in the battery when connected to recognise that a battery is present and to start the charging process but the MPL will recognise a battery with only one volt. This means that the MPL charger will attempt to recover and charge a battery that is completely flat, whereas other chargers would not be able to start charging at all. At the start of each charge, the MPL charger tests the battery to determine if it is deeply discharged or if sulphation has occurred, and the correct recovery algorithm is automatically applied.

“After the deep discharge test, the constant current charge provides the fastest possible return of energy to the battery. Even deeply discharged batteries can be recovered in this way.

“After the completion of charging, the MPL charger switches to the standby or float mode, which compensates for self-discharge and holds the battery at peak charge ready for use.” Chris adds: “Using the MPL can dramatically improve the performance of batteries that have been stored and reduce warranty costs along with improving customer satisfaction.”

To read the full Autotechnician magazine click here.